Compared with other rigid supports, mine roof supports are more retractable and stable and reliable in load-bearing capacity, adapt to the load and deformation of soft surrounding rocks, have high section utilization, and support easy support. Mine roof supports are classified by purpose: steel supports for coal mines, steel supports for iron mines, steel supports for gold mines, steel supports for copper mines, steel supports for lead-zinc mines, steel supports for railway and highway tunnels, steel for diversion culverts of hydropower stations bracket.

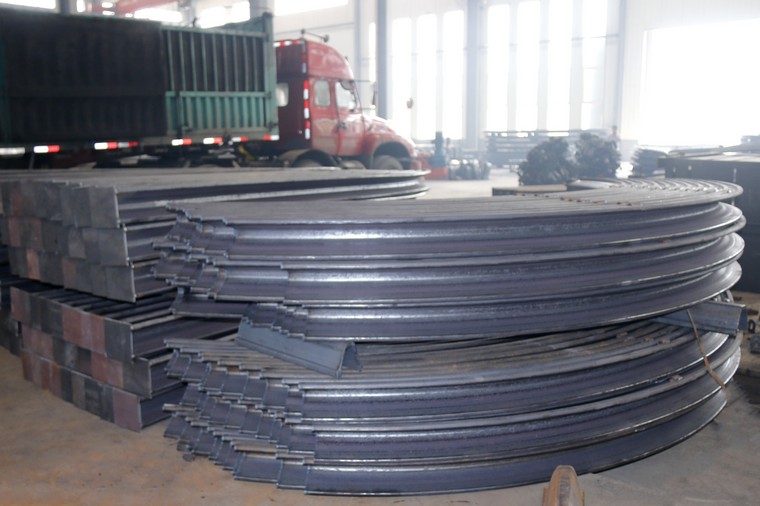

The mine roof support is safe and reliable, effectively reducing the occurrence of roof fall, slabs and other accidents, and improving the stability of the mine ventilation system. Research on the popularization and application of mine roof supports has improved the safe production conditions of mines and reduced production costs. It conforms to the national policy of replacing wood with steel and has good environmental and social and economic benefits. The mine roof support is a kind of steel with a cross-sectional shape like the English letter "U". U-shaped steel produced in various countries has different cross-sectional shapes, geometric parameters and materials. At present, U-shaped steel produced in China mainly has four types: U18, U25, U29, and U36. Among them, U18 and U25 belong to waist positioning; U29 and U36 belong to ear positioning. Due to its low carrying capacity, U18 is rarely produced.

The stress state of the mine roof support is that the back wall is filled and compacted to make it evenly compressed. When the pressure value of the surrounding rock used for the mine roof support reaches a certain value, the support will be compressed and the surrounding rock will act on the mine roof support The pressure on the upper surface is reduced, so as to prevent the support from being damaged by the surrounding rock pressure being greater than the bearing capacity of the roof support.