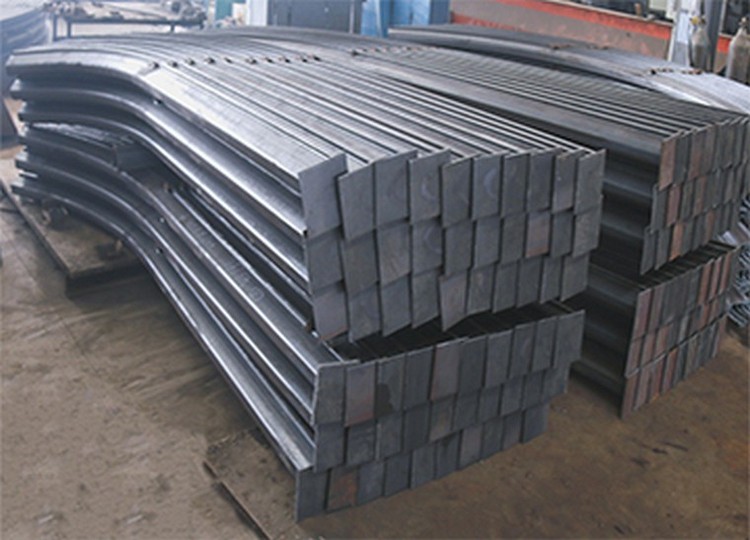

The "U"-shaped design of the tunnel roof support is to achieve a better stress state. These are also uniformly compressed after the wall is filled and compacted, and are used as the surrounding rock pressure value on the tunnel roof support. After a certain period of time, the tunnel roof support will be compressed, which relieves external pressure and reduces the risk of underground operations.

Compared with other rigid supports, tunnel roof support are more retractable and stable and reliable in load-bearing capacity, adapt to the load and deformation of soft surrounding rocks, have high section utilization, support easy support, small maintenance, high support recovery and reuse rate, and reduce pits The use of wood has obvious environmental benefits.

According to the actual situation of the coal mine, flexibly select the model, structure and shed distance of the tunnel roof support, correctly guide the construction of the tunnel roof support, ensure its effective and reliable work, and speed up the tunneling speed and reduce the amount of repairs in the later stage of the tunnel. Safe production, extended service life, better technical and economic benefits, and full play of the support performance are of great significance.