As the national environmental protection and national policies become more and more popular, mining pits can no longer be purchased from natural pine forests but only artificial pine forests. Due to the relatively short age of the artificial pine forest, the support strength of the bracket is affected to a certain extent, and the market price of pit wood has been rising all the way. In addition, national industrial policies have increasingly demanded the safe production of coal mines. Support method. Therefore, the use of wooden shed supports is at a disadvantage both in economic, safety and environmental benefits. Obviously, replacing wooden supports with steel supports for mining has become one of the major contents of coal mine support reform.

For the workers working under the mine, first of all, the underground roadway is the place of coal mine production. The safety management of the mine roadway is one of the most important tasks in the safety production management of coal mines. Each mine must set up a mine roadway safety management agency. Establish and improve the safety management responsibility system of mine roadways.

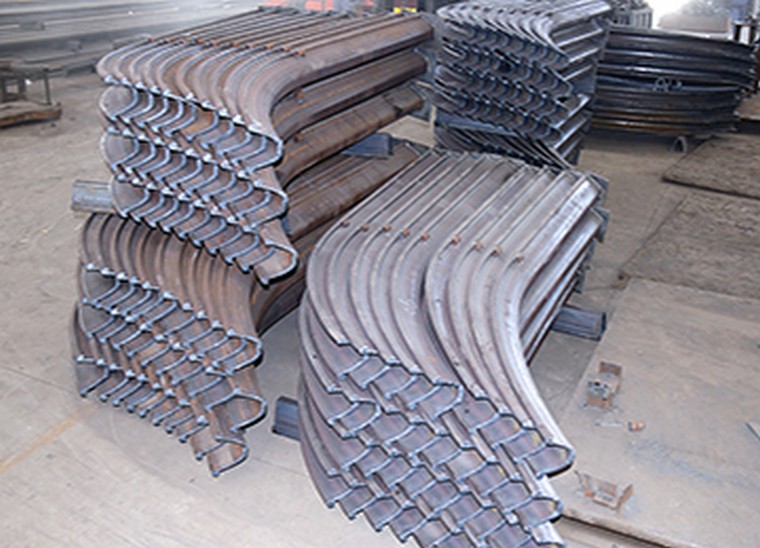

Underground roof support are mainly used in mine tunnels, secondary support of mine tunnels, and support and support of mountain tunnels. The use of U-shaped steel brackets can effectively reduce the occurrence of accidents such as roof fall and sheet gangs, which is safe and reliable, and improves the stability of the mine ventilation system. Underground roof support is used to better solve the problem of tunneling support.